What Does Digital Printing Do?

What Does Digital Printing Do?

Blog Article

Some Of Digital Printing

Table of ContentsThe Main Principles Of Digital Printing Digital Printing Things To Know Before You Get This

The favorable plate, with its smooth surface, attracts oil-based inks and repels water. In contrast, the negative plate, with its harsh texture, soaks up water and repels oil. Rubber rollers are after that made use of to transfer the photo from the plate to the corrugated surface.Corrugated paper can occasionally confirm to be a difficult surface to publish on, yet Litho prints to a different surface and is after that laminated to it, making it easy to print high-grade images. It can be exceptionally regular, even for long terms. The extra you publish, the cheaper the expenses come to be for Litho.

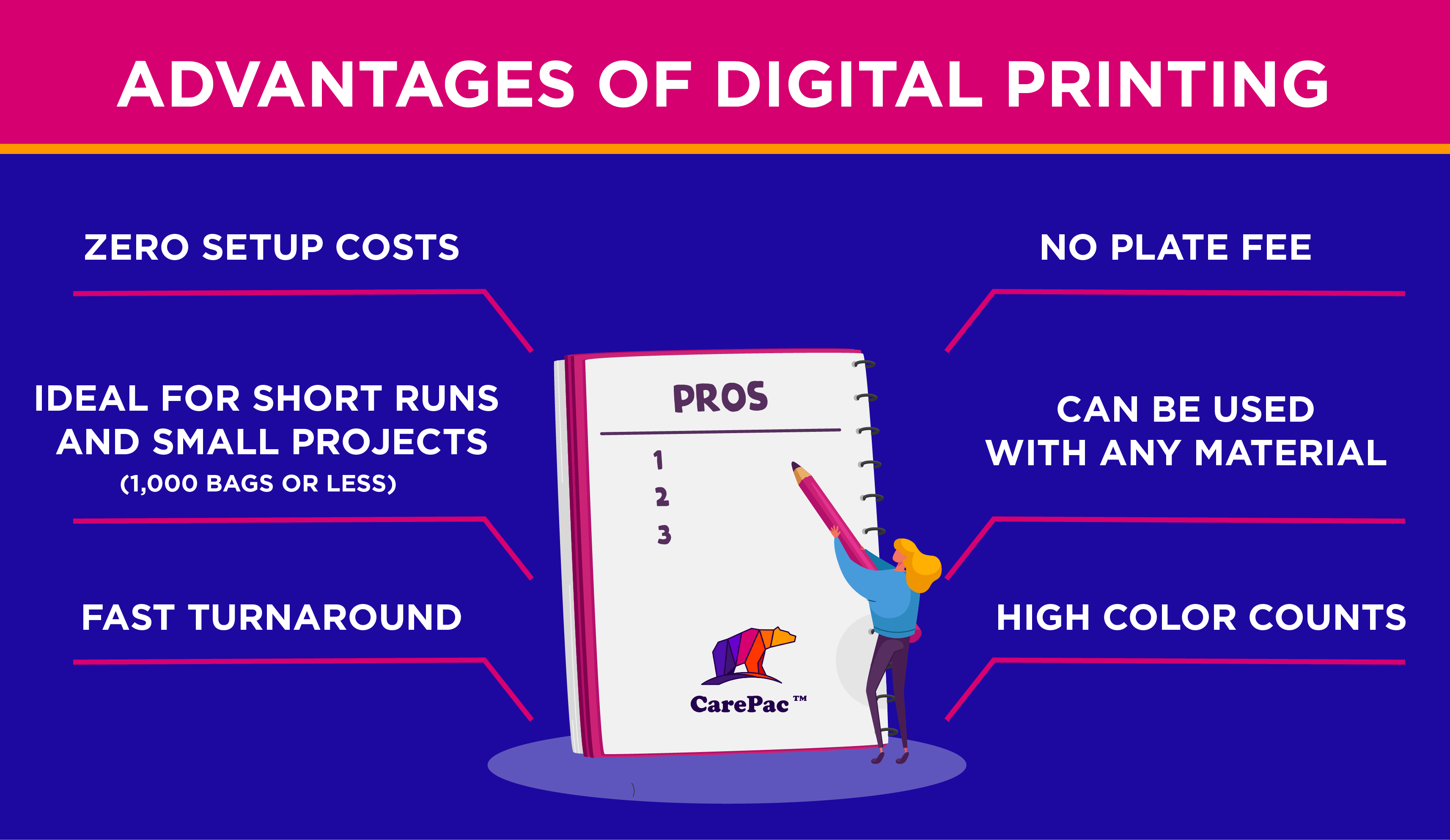

If you have enough time and budget, and a big volume of a solitary style, after that there should not be an issue. What Litho does not offer you is specifically what Digital does, modification. More on that particular later. Pricey set up Longer turnaround No Variable Information Printing Smaller shade range, colors can be much less brilliant Digital printing is the process of printing electronic pictures directly onto the corrugated substratum using a single-pass, direct-to-corrugate technique - Digital Printing.

Digital Printing - The Facts

This streamlines the process and opens many advertising and marketing and design possibilities!:. Conventional printing techniques like Offset Printing have been the status for a long time, and one of the biggest factors is that at huge quantities, it wins on price. However that's if you plan to make use of a solitary style for all of your product packaging - those days are over.Offset Printing needs money and time to produce a Printing Plate, while Digital Printing permits you to simply submit an art file( as lots of as you want )to the Press. Variable Data Printing (VDP)Print-on-demand Distinct product layouts Seasonal+Promotional messaging Cost-efficient short manufacturings Quicker turnarounds If your job has a solitary layout, Litho could be a much better choice because of the scaling costs of production. There are other factors to pick Litho, yet as pointed out previously, the days of a one-size-fits-all design more than. That indicates that all brand names need to readjust their technique asap. When they purchase their items, consumers have a cravings for online marketers to create this personal experience for them-and digital helps you to do this. Today, most brand names underuse print personalization due to the fact that they are simply not aware of the practice's feasible advantages and that digital printing is the method to get there. These are a few of the most dependable and effective digital printers on the marketplace.

. With digital printing, you have the power to create a new appearance for your display screen every time you need a brand-new production run. If you need a single style for an entire campaign, then possibly Litho is appropriate for you. However remember, your up-front budget and lead time will have to be taken into account. Required help making a decision Bennett is a leading packaging and retail display screens manufacturing company striving to shield and advertise our customers 'items with tailored corrugated solutions. We will certainly companion with you every action of the method. With our totally integrated design-to-delivery procedure, we can be the solitary vendor source. We are an acclaimed supplier of practically anything corrugate.

We provide every little thing from plain brownish delivery boxes to advanced, high-graphic printed point-of-purchase display screens and every little thing in between. They vary in size and innovation, however they permit you to publish art files straight to the press, rather than producing printing plates. Digital Printing is when you publish a digital-based picture onto some form of print media.

Report this page